Decanter Centrifuge

Focus on Your Goals in Mining and Drilling Applications

Han Mekatronik is aware of the responsibility of working without sacrificing quality in the globalizing world and international competition; It is improving day by day with the equipment, service, teamwork and strong staff it offers.

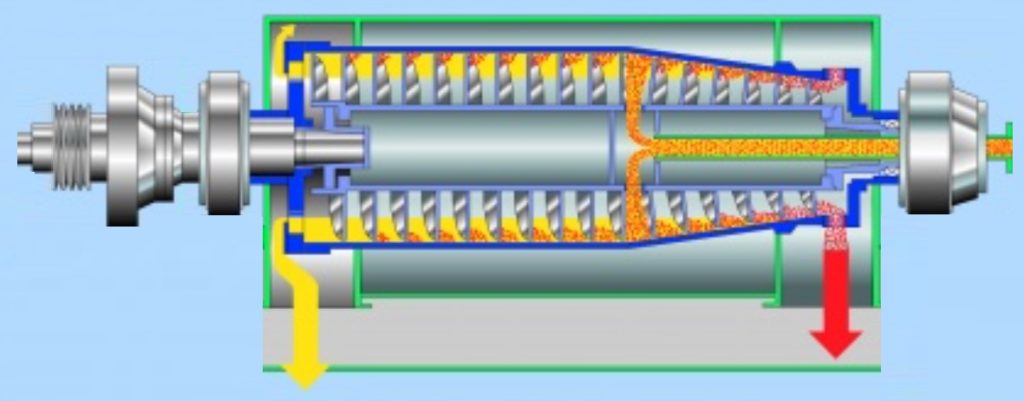

Han Mekatronik decanter centrifuges are a key component in a topquality drill slurry treatment process.

This technology efficiently removes most of the fine particles that traditional slurry treatment equipment cannot deal with.

Specially designed and built for heavy-duty jobs in this field,the

Han Mekatronik HANS range of decanter centrifuges is able to

handle large amounts of feed solids, as well as coping well with abrasive and coarse particles.

HANS decanter centrifuges are available with a range of modules ideally suited for every kind of solids separation job in

conjunction with the oil drill slurries used on drilling rigs, exploration rigs and foundation pile drilling, tunnel Boring Machines.

These modulesrange from fully automated operation to simple hands-on capabilities, providing effective solutions to all your slurry treatment and separation issues.

The advantages we provide

Special design for increased performance with optimized process configuration,

Maximum wear resistance with tungsten carbide plates for longer operating life,

Option to work with a single machine at high flow rate,

Superior protection against abrasive and corrosive materials,

Anti-wear measures designed to be replaced and repaired on site when necessary,

Drive system with intelligent kinematics for high differential speeds and torques that allow high-capacity solids processing,

ATEX certified special design that provides general flame protection and explosion protection standards according to the requirements of the process,

Ability to work at low and high temperatures,

Less space requirement for installation,

Design in accordance with occupational health and safety standards,

Low energy consumption and low labor cost,

Continuous process optimization through PLC and SCADA control,

low maintenance cost,

Solution-oriented and fast service.

| SPECIFICATIONS OF HANS WASTE DECANTER CENTRIFUGE | ||||

| Model | HANS360 | HANS440 | HANS510 | HANS650 |

| Bowl Diameter | 360mm | 440mm | 450mm | 550mm |

| Bowl Length | 930mm | 1250mm | 1000mm | 2200mm |

| Effective Capacity | ≤30m³/h | ≤40m³/h | ≤60m³/h | ≤90m³/h |

| Max Capacity | ≤45m³/h | ≤60m³/h | ≤80m³/h | ≤110m³/h |

| Max Bowl Speed | 4200RPM | 3800RPM | 3250RPM | 3100RPM |

| Max G Force | 2835 | 3550 | 3550 | 3010 |

| Main Motor Power | 18/37kw | 22/45kw | 75kw | 75/110kw |

| Helper Motor Power | 5,5kw | 7,5/15kw | 15kw | 15/30kw |

| Weight | 4200kg | 4750kg | 5800kg | 6400kg |

| Dimension | 2640x720x920mm | 2960x1550x1730mm | 2750X1550X1750mm | 4010X2000X1850mm |