Concrete Batching Plants

What is a Concrete Batching Plants ?

Concrete plants are facilities where ready-mixed concrete is produced by combining cement, water, sand, gravel, crushed stone, and various additives. The prepared concrete is then loaded into truck mixers or transport trucks for delivery to construction sites.

Main components of a concrete plant include:

Aggregate bins: For storing sand, gravel, and other aggregates

Aggregate scales & weighing belts: For accurate measurement of aggregates

Water, cement, and additive weighers: For precise dosing of each material

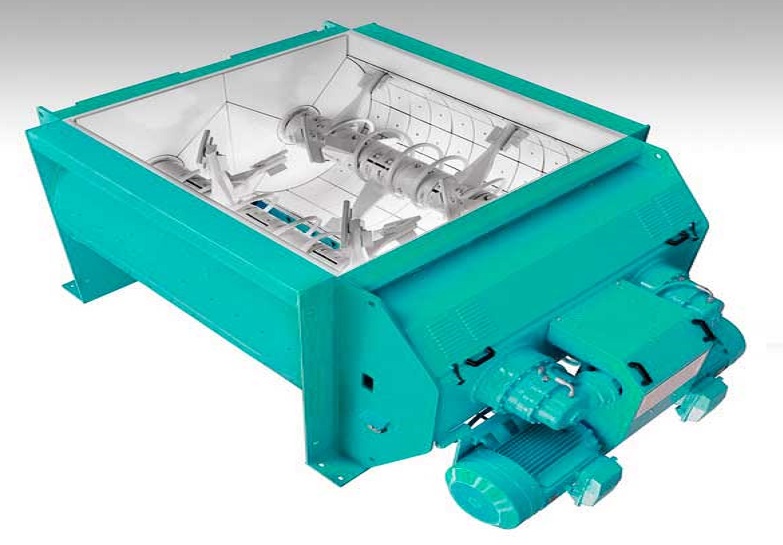

Mixer feeding belt and main chassis with mixer: Where materials are combined to produce concrete

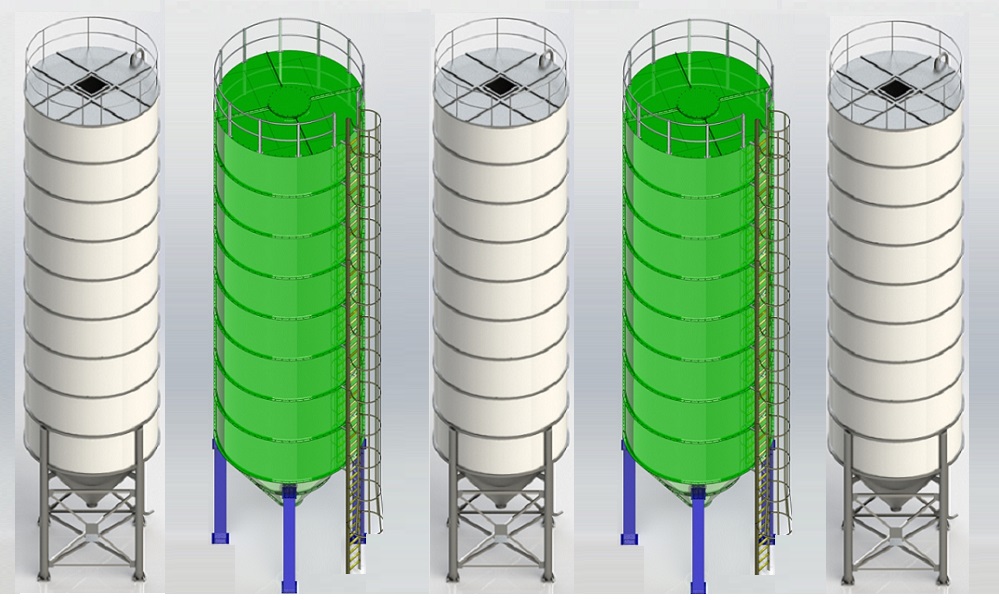

Cement silos: For storing and supplying cement

Auxiliary equipment: Includes water heating or cooling systems for special cases

Electrical panels & automation systems: For controlling and monitoring the entire plant

Types of Concrete Batching Plants

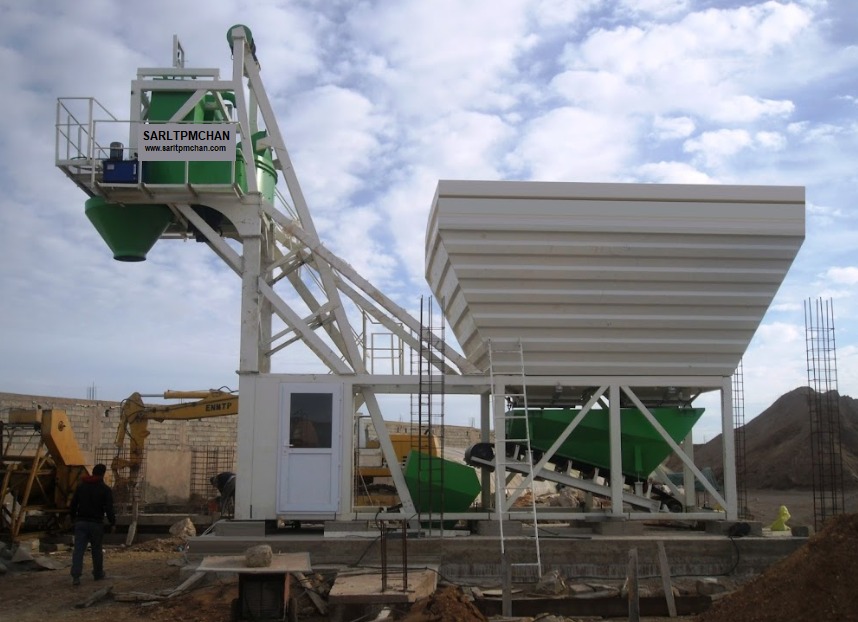

1. Mobile Concrete Batching Plants

Mobile plants are preferred for short-term projects or projects that frequently change location due to:

Quick installation (1–2 days)

No concrete foundation required

Easy transportation

2. Stationary Concrete Batching Plants

Stationary plants are designed for long-term projects that require high-quality concrete. They offer:

High capacity and efficiency

Reliability and flexibility

Commonly used in bridges, harbors, tunnels, dams, buildings, and roads

3. Dry Concrete Batching Plants

Dry plants are popular because they provide:

Easy installation

Low cost, including transportation

Concrete can be transported over long distances without water

Mixing occurs in the transit mixer at the site, unlike other plant types

4. Compact Concrete Batching Plants

Compact plants offer:

Easy installation, even in narrow areas

Economical transportation

Lower cost compared to other types

Suitable for container transport

Customization

We produce concrete with the mixer type you want.