Concrete Mixers

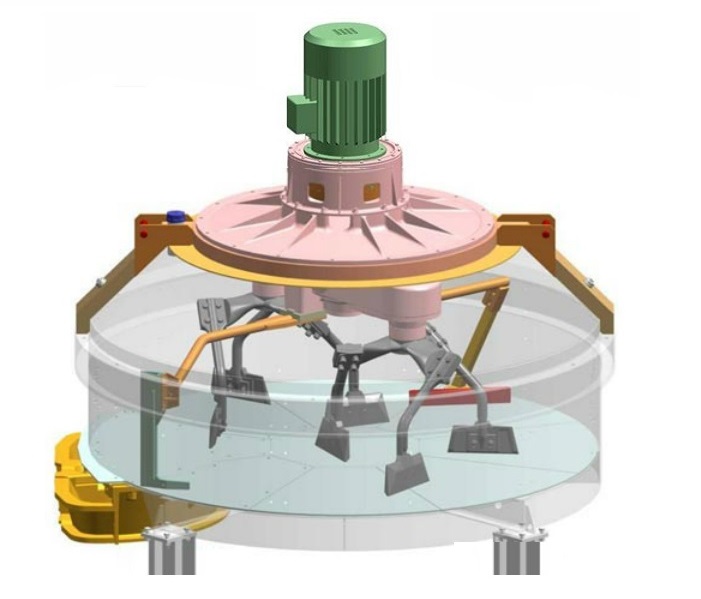

HANMIX mixers are made of specially designed bearing housing and Mixer Shaft sealing, which is very different from its counterparts, 200 micron very special chrome-plated on the mixer shaft, bronze bushing with graphite on the outside and steel inside, and polyurethane sealing elements.

Thanks to the special lubrication channels, the lubrication is constantly pressed from the outside to the inside by the automatic lubrication system, the oscillating grease creates a natural seal and prevents the cement liquor from passing to the bearings. In case of a leaking problem, the bearings are equipped with a special product that prevents the cement slurry from entering the interior, except for the mixer. the design is housed inside the enclosure, so with proper and routine maintenance, the estimated life of each bearing and sealing assembly can be considered to be 500,000 m³ for mixers of 1m³ to 2m³ and 1000,000 m³ for mixers of 3m³ to 6m³.

Single shaft

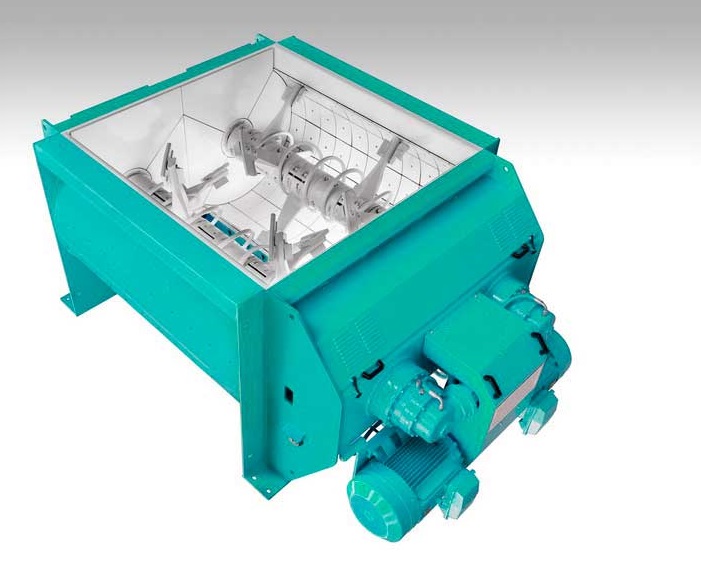

Two Shaft Mixer

Planetary Mixer

Mixing of the product takes place using 2 parallel axes equipped with levers and bolt-on blades made of cast Ni-Hard steel. The movement of the mixing parts is provided by one or more electric motors combined with gearboxes and torque dividers moving on two shafts.

HANMIX twin shaft mixers of the sizes ranging from 1.25 m³ to 6.0 m³ were entirely re-engineered, incorporating a lot of innovations in the series that provide for more customer benefit. All functional devices, as electric motors.

In our HANMIX Mixers, we provide Fag bearing, automatic lubrication, high pressure automatic internal washing system and ni-hard internal wear-resistant products as standard. It has been proven that Ni-Hard wear plates are 3 times longer in wear resistance than their counterparts.

FAST MIXING SPEED

Two counter-rotating mixing shafts synchronized with each other and connected to the arms and vanes create intense turbulence in the overlap area, dispersing and finely dispersing the cement into the aggregates. The inclination of the arms and wings creates a horizontal ring movement with perfect homogenization of all components.

Profiled mixer cover to prevent build-up and reduce cleaning time

Double paddle arrangement for more mixing efficiency

high pressure cleaning system

Customization of your mixer to suit your unique needs

Multiple discharge opening with actuators and independent hydraulic group

Customization of your mixer to suit your unique needs