Direct fired thermal system

Model: MUH 1.75 – 9.50

Drum Dimensions

Diameter 1.75 Cm x Length 9.50 Cm.

Processing Capacity: 15-33 TPH

Optional Mobile

Model: HUS 2.20 -12.00

Drum Dimensions

Diameter 2.20 Cm x Length 12. Cm.

Processing Capacity: 30 – 55 TPH

Optional Mobille

Model: EMR 2.40 -15.5

Drum Dimensions

Diameter 2.40 Cm x Length 15.5Cm.

Processing Capacity: 55-110 TPH

Stationary

Combustion and Drying Systems we Manufacture

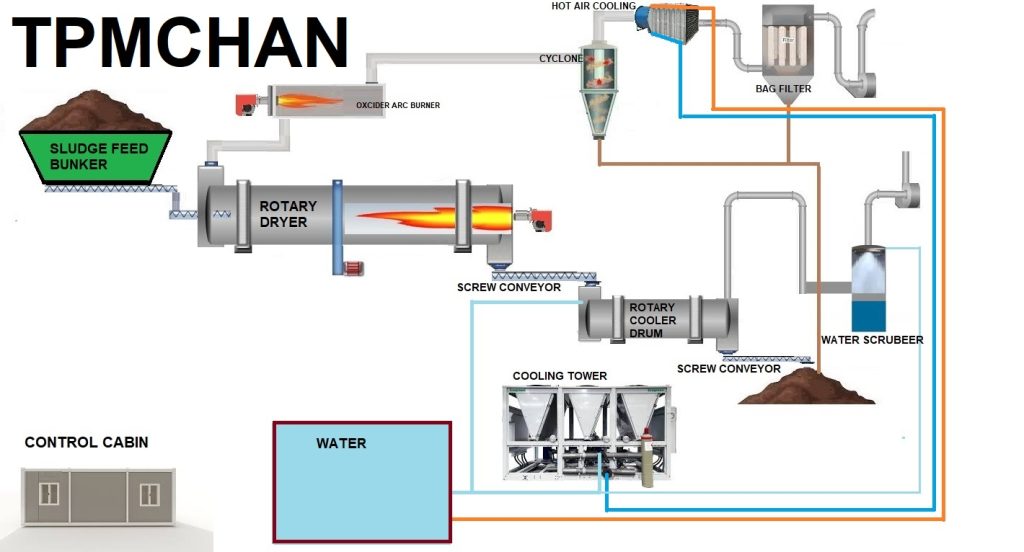

Technical Explanation of the Contaminated Soil Treatment Process This system is a process that uses the principle of direct firing and high-temperature oxidation for the cleaning of contaminated soil, offering a high Destruction Removal Efficiency.

Section 1: Rotary Kiln Process (Direct Firing / Combustion)

This stage is the essential step where all hydrocarbons and carbons within the contaminated soil are destroyed by combustion.

Mechanism of Action: The system operates on the principle of Direct Firing. The soil is directly exposed to a flame inside the Rotary Kiln.

Temperature Range: The contaminated soil is exposed to temperatures between 450 C and 600 C inside the Rotary Kiln. The process becomes effective when the ambient temperature starts from 450 C.

Crucial High-Temperature Exposure: In the last 5 meters of the Rotary Kiln, the oily soil is directly discharged into the center of the main flame’s core. This exposure subjects the soil to the 1700 C temperature of the flame.

Combustion of Hydrocarbons: Due to this high heat exposure, the hydrocarbons within the soil automatically ignite and burn (flash). This is a direct combustion process, not vaporization (desorption).

Solid Output: The treated soil coming out of this process contains no carbon.

Section 2: Afterburner (Thermal Oxidizer) Process

This stage is the assurance step where gaseous Volatile Organic Compounds that escape from the Rotary Kiln are completely destroyed for the last time.

Purpose: To completely destroy the gaseous Volatile Organic Compounds escaping from the Rotary Kiln.

Combustion Temperature: The gases are exposed to temperatures between 1000 C and 1200 C.

Residence Time: To ensure Destruction Removal Efficiency, the gas residence time in the combustion chamber is approximately 2 seconds.

Destruction Removal Efficiency: Thanks to the optimized high temperature and residence time, all Volatile Organic Compounds are destroyed, and a Destruction Removal Efficiency of 99.99% is guaranteed.

Section 3: Treated Soil and Final Quality

Soil Purity and Moisture: When the soil enters the kiln with a moisture content of 3%, the final cleanup rate (purity) of the treated soil is 0.03%.

This figure represents the total cleanup rate for the process.

The treated soil is re-moisturized with water 7-10% after the thermal process to cool it down and prevent dust formation.

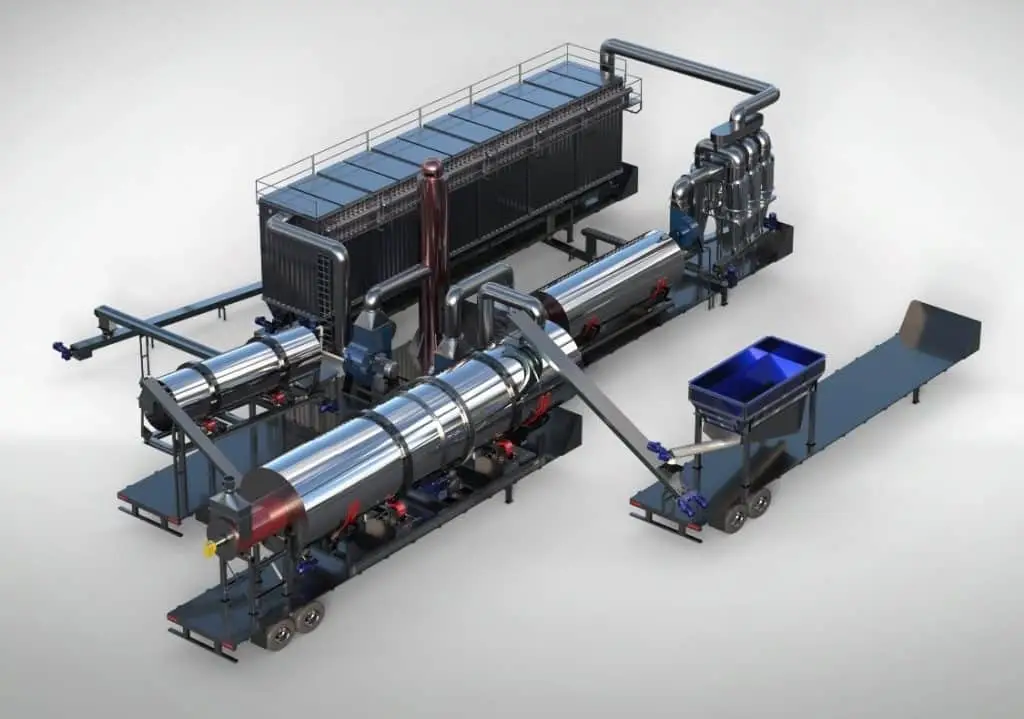

Mobile Solid Waste Incineration System

Engineered for remote locations such as oil drilling sites, refinery tank farms, and industrial facilities, this system delivers high-temperature, fast, and environmentally compliant solid waste disposal.

✓ Key Features

True Mobility: Trailer-mounted or skid-mounted configurations

High-Temperature Operation: Incineration at 450–600°C

Energy Recovery: Optional heat recovery for process reuse

Environmental Compliance: Compatible with full flue-gas cleaning systems and purification filters

Applications of Our Thermal Processing Systems

Our engineering and manufacturing capabilities cover a wide range of industrial waste streams:

Tank Bottom Remediation

Drill Cuttings Remediation

Oily Soil Drying

Hazardous Waste Incineration

Animal Waste Drying

Wastewater Sludge Drying

Oil Sludge Drying

Pulp & Paper Industry Drying Solutions

TPMCHAN Operational Advantage Package

Speed & Mobility

Trailer-ready design

100% mobile configuration

Installation and commissioning in as fast as 8 hours

No crane required for setup

High Capacity

Processing rates from 10 to 110 tons/hour.

Full Automation

PLC-based fully automatic control

Automatic moisture measurement

Automatic burner flame-intensity control

Safety & Premium Quality

Emergency stop safety system

Components from Bosch, Telemecanique, and Schneider

Heavy-duty, field-proven construction

Service & Support

24/7 remote technical support

24/7 fast after-sales service

Easy maintenance access

Guaranteed spare parts availability

Commercial Value

Best-in-class price/performance ratio

7-day machine delivery time

Why TPMCHAN?

Because every system we build is designed with one goal:

maximum performance, reliability, and environmental responsibility — anywhere in the world.